Nanocellulose or nano-structured cellulose is a modern form of cellulose with a dimension in the nanoscale. Nanocellulose contains unique properties if we compared it to cellulose and its microfibers. It has great properties such as renewability, higher surface area, flexibility, good tensile strength, higher surface area, and abundant availability.

Nanocellulose exists as cellulose nanocrystals(CNC), cellulose nanofibrils (CNF), and bacterial cellulose (BC). Cellulose nanocrystal (CNC) is generally prepared via acid hydrolysis of pure cellulose mostly using inorganic acids like HCl, H2SO4, etc.

CNF or Cellulose nanofibrils can be prepared easily by mechanical disintegration process in a high-pressure homogenizer or an ultra-fine grinder, or a microfluidizer using high shear forces and potentially in combination with either chemical or enzymatic pre-treatment for reducing energy consumption rate. BC or Bacterial cellulose is prepared via cellulose-producing bacteria such as Acetobacter xylinum.

Structure of Nanocellulose

It contains highly ordered crystalline regions along with some amorphous regions in varying proportions, depending on source types. This organic biopolymer consists of the linear homopolysaccharide of β-1,4-linked anhydrous-d-glucose units as the repeating unit. The various amounts of hydroxyl groups and strong hydrogen bonding networks make this component outstanding. The mostly crystalline regions are attached properly with amorphous regions in this compound.

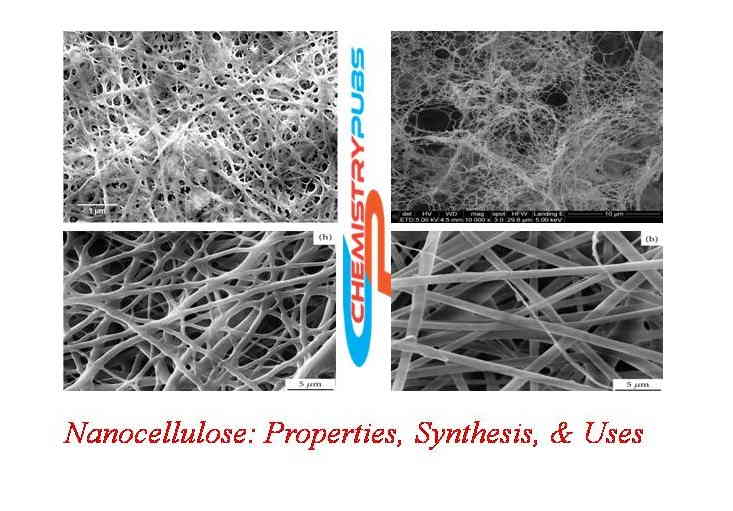

The suspension of nano cellulose may not be homogeneous because of the presence of various structural components, including cellulose nanofibrils and nanofibril bundles. The identified lateral dimensions of this material range from 5 to 25 nm, and the longitudinal dimension ranges from a few 10s of nm (nanometer) to several microns.

Properties of Nanocellulose

Nanocellulose is a non-toxic and biodegradable polymeric molecule. The density of this biopolymer is low. It has electric conduction properties. It has biocompatibility and higher mechanical strength properties. The crystallinity of this compound is better which makes it outstanding.

Types of Nanocellulose

There exist three types of this compound whose descriptions are given below:

Cellulose nanocrystals:

CNC or Cellulose nanocrystals are produced easily by treating pure cellulose with acid hydrolysis. Generally, concentrated sulfuric acid is used for removing the amorphous regions of cellulose, and the crystalline regions are left alone. The produced compound is about 90% pure, and the sulfate groups remain attached at the surface of the fibers as impurities. The length and diameter of this compound vary from a length of 200–600nm to a diameter of 3–40nm.

Cellulose nanofibrils:

Cellulose nanofibril contains lateral dimensions of the micrometer range and the longitudinal dimension of the nanometer range. This material is produced by high-pressure grinding of cellulosic pulp suspension and strongly entangled networks. The crystallinity of this material is about 90%. Each single CNF contains amorphous as well as crystalline cellulose. The diameter of CNFs ranges from 5 to 50 nanometers and the length is a few micrometers.

Nanocellulose can be extracted from pure cellulose by three types of processes: (1) mechanical treatments (2) chemical treatments and (3) a combination of chemical and mechanical treatments.

The mechanical treatment involves grinding, milling, and homogenization process. The chemical treatment involves oxidation with TEMPO.

Bacterial cellulose:

Bacterial cellulose or microbial cellulose is generally produced from bacteria like Acetobacterxylinum bacteria. It does not require additional handling to remove contaminants like lignin, pectin, and hemicellulose to produce this cellulose. It is necessary to the addition of molecules from tiny units (Å) to small units (nm).

In the biosynthesis of this compound, the chain of glucose must be provided inside the bacterial body and discharged out through minor pores present on the cell wall. The ribbon shaped bacterial cellulosic nanofibers are produced when glucose is fused with the cell wall of bacteria. The ribbon-shaped bacterial cellulosic nanofiber contains 20–100 nm long length which is a unique nanofiber system.

Preparation of Cellulose Nanocrystals:

Cellulose Nanocrystals (CNC) has a diameter of less than 100 nm and a length of less than 500 nm by intermolecular interaction of cellulose macromolecules in hydrogen bonds. Cellulose Nanocrystals are generally prepared through acid hydrolysis or enzymatic hydrolysis of pure cellulosic pulp. Concentrated acid must be needed for the preparation of this CNC.

The enzymatic hydrolysis process needs a long time to get CNC. The amorphous regions are degraded quickly during the acidic hydrolysis of cellulose, whereas crystalline regions are unchanged. The first CNC compound was prepared from pure cellulose by Nickerson and Habrle in 1947 with the help of hydrochloric acid and sulfuric acid mixtures. The stable colloidal suspension of CNC was prepared by Ranby in 1951.

There exist various modern methods to prepare this compound like solid acid hydrolysis, organic acid hydrolysis, enzymatic hydrolysis, oxidative degradation, and subcritical hydrolysis.

Mineral Acid Hydrolysis process

The mineral acid hydrolysis with pure cellulose is very much used for the preparation of CNCs. The mechanism relates that acid provides hydrogen ion and enter into the amorphous regions of cellulose to break the 1,4-β-glycoside bonds. As a result, the amorphous regions are hydrolyzed easily. The crystalline region of cellulose remains unchanged because it contains a compact structure that averted the permeation of the acid molecules. Thus we get CNC obtained by the hydrolysis of mineral acid.

There are various mineral acids like sulfuric acid, hydrochloric acid, phosphoric acid, and hydrobromic acid, and their mixed acids are used for the production of this compound.

Concentrated sulphuric acid is very much used for the production of this compound. Generally, the pure cellulosic material with 58% concentrated sulphuric acid is heated at 60°C for 4 hours to get nanocellulose. In this process, the yield of this compound is about 75%.

The thermal stability of the produced compound is relatively low due to the presence of the sulfate group. It creates a great barrier for the thermal process during composite production. The thermal stability can be increased by neutralization with NaOH solution.

Hydrochloric acid is also used greatly for the preparation of CNCs. It requires 2 to 4 hours of reaction with pure cellulose and 2.5 -6.0 N hydrochloric acid at 60°C temperature. The yield of CNCs is about 88% to 93% by this process. The maximum degradation of CNC is 363.9°C which was identified by TGA analysis

Hydrobromic acid (HBr) can be used in the production of this compound. Generally, 2.5 Molar concentrated HBr acid is used under 100°C with sonication for 3 hours to the production of CNC compound. The yield of CNC is 60% by this process. The diameter of produced CNC by this process is about 20.0 (±4.4) nm

The mixture of sulfuric acid (98%, w/w), hydrochloride (37%, w/w), and H2O at a ratio of 3: 1: 6 (v/v) can be used at 80°C by ultrasonicator under heating for 8 hours to produce CNC (Zhang et al.). The diameter of the produced CNC ranges from 60 to 570 nm.

Characterization of nanocellulose:

Scanning Electron Microscopy: The morphology of the CNC surface can be known by using a scanning electron microscope.

FTIR Spectroscopy: This method is used to identify the functional group of CNC molecules.

X-Ray Diffraction (XRD) Analysis of CNCs: X-ray diffractometry is used at room temperature to measure the crystallite index of nanocellulose.

Thermogravimetric Analysis (TGA): The thermal behavior of prepared CNCs can be identified by a Thermogravimetric Analyzer system.

BET Analysis: The surface areas of prepared CNCs can be examined by the BET analysis method.

Applications of Nanocellulose

This organic polymer is used in the pharmaceutical, food, and medical industries which are discussed below:

Composite production

This material is used as an interesting material for reinforcing plastic production. This compound can be spun into filaments that are very strong and stiffer than spider silk. It is used to improve the mechanical properties of thermosetting resins, rubber latex, starch-based matrixes, and soy protein. The composite with this compound has a gas barrier and fire retardancy properties.

Food industry

This material is used food industry to produce food packaging material because it prevents any spoiling food contents and entry of oxygen into the food contents. This material is getting popular and replaces the use of polystyrene-based foams to manufacture food packaging systems.

This organic compound is a very important item for the production of flavor carriers, food thickeners, and suspension stabilizers.

Paper Products

It contains good fiber-to-fiber bond strength and acts as a barrier in grease-proof type papers. It improves dry and wet strength in commodity types of board and paper products.

Electronic product manufacturing purposes

This compound is used to produce nanocellulose sheets which can be used for electronic displays and windows.

It increases the mechanical properties of rubber latex, soy protein, thermosetting resins, and starch-based matrixes.

Pharmaceutical Applications

This compound is used for the production of antimicrobial films, tissues, and water-absorbent pads in the pharmaceutical industry. Many intestinal disorders are treated by tablets comprising dry solid nanocellulose.

Frequently Asked Questions (FAQs)

What is nitrocellulose?

Nanocellulose is a modern form of cellulose with a dimension at the nanoscale level. It consists of the linear homopolysaccharide of β-1,4-linked anhydrous-d-glucose units as the repeating unit.

What are the types of nanocellulose?

There exist three types of nanocellulose namely cellulose nanocrystal (CNC), Cellulose nanofibril (CNF), and bacterial cellulose.

What is cellulose nanocrystal (CNC)?

It is a crystalline form of cellulose chain which a length and diameter of the compound 200–600nm and 3–40nm respectively.

What is Cellulose nanofibril (CNF)?

It is a crystalline cellulose whose crystallinity is about 90%. The diameter of CNFs ranges from 5 to 50 nanometers and the length is a few micrometers.

What is bacterial cellulose?

Bacterial cellulose or microbial cellulose is generally produced from various bacteria like Acetobacterxylinum bacteria.

What is the function of cellulose nanocrystals (CNC)?

CNC has biocompatibility and higher mechanical strength properties. Cellulose nanocrystals are biodegradable.

Where are cellulose nanocrystals (CNC) found?

The source of cellulose nanocrystals (CNC) is various plants, algae, fungal bacteria, and even some marine animals.

What are the advantages of cellulose nanocrystals (CNC)?

Cellulose nanocrystals (CNC) have good crystallinity indexes, nontoxicity, and good mechanical properties.

References

Yu H, Qin Z, Liang B, Liu N, Zhou Z, et al. (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. Journal of Materials Chemistry A 1: 3938-3944. Link: https://goo.gl/4cF5Nm

Liu D, Zhong T, Chang PR, Li K, Wu Q (2010) Starch composites reinforced by bamboo cellulosic crystals. Bioresource Technology 101: 2529-2536.

Klemm D, Kramer F, Moritz S (2011) Nanocelluloses: A New Family of Nature-Based Materials. Angewandte Chemie International Edition 50: 5438-5466. Link: https://goo.gl/vw5mo8