A water distiller is used to produce contaminant-free water by transforming water into vapor before condensing into a liquid state. It can remove impurities, including germs, heavy metals, and arsenic from water during evaporation because they cannot transform into steam. The distiller in this apparatus cools the evaporated water and transforms it into pure, mineral-free drinkable water. Distilled water has various applications including fermentation, the medical industry, clinics, and organic chemistry labs.

It helps to filter away non-volatile organic molecules, most minerals, and a variety of chemicals in addition to charged ions. It is estimated that 95% of the minerals, including salt, sulfate, nitrate, and arsenic, will be eliminated it. Various biological pollutants like bacteria, viruses, and cysts are also eliminated from this apparatus. This apparatus is mainly used to produce smaller amounts of water for drinking and cooking purposes due to its high expense of operating process. The reverse osmosis system gets popular when more treated water is needed.

Principle of Water Distiller

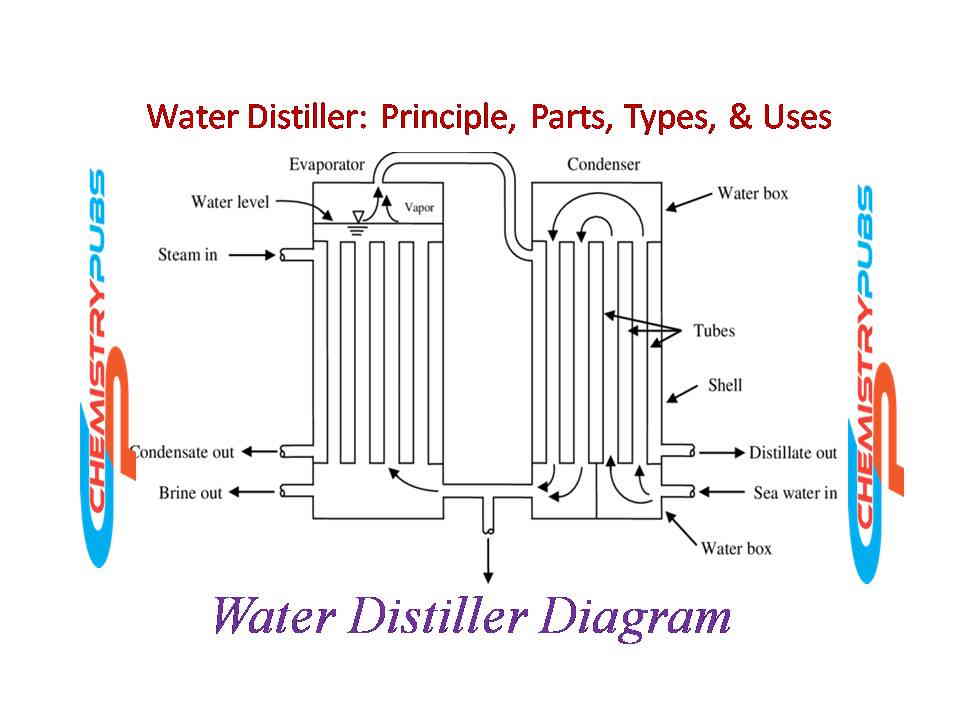

Water distiller uses the evaporation and condensation mechanism to produce deionized water. Water can be transferred into vapor by adding thermal energy to this apparatus. This process helps to enable the molecules of water to dissociate from the molecules of other substances that have been diluted or combined with it. Then the water vapor turns into liquid after passing it into a condenser. Distilled water shows pristine qualities and is essentially free of impurities.

Parts of a Water Distiller

Vapor generator/Boiling tank

The vapor generator of the water distiller is made of stainless steel to produce steam in this apparatus.

Water Level Gauge

This part helps to recover the evaporated liquid when the amount of water in the liquid phase in the boiling tank drops.

Control valve

This valve helps to flow the water into the vapor generator tank to be controlled mechanically or electromechanically.

Immersion resistors

This part has the ability to produce heat when an electric current passes through them. They are shielded from the external environment by a metal plate.

Refrigerator water outlet

This line helps to condensate the water vapor.

Condenser

This part cools and returns the vapor to its liquid phase after losing thermal energy. This part is run by forced convection, which involves circulating low-temperature fluids around the line where the vapor flows.

Filter

A definite amount of activated carbon filters is used in water distillers near the condenser or collector exit. These remove any flavors or particles which may be found in condensed water.

Distilled water container

This container helps to collect the liquid that has undergone distillation. This container is generally made of polytetrafluoroethylene, polyethylene, or polypropylene.

Types of Water Distillers

There are many types of water distillers which are given below:

Manual distiller system

This distiller system can produce 1 gallon of water at once. Generally, 1-gallon-sized glass or plastic jars are used in this distillation system. The capacity is determined by calculating the amount of water a manual distiller can generate in an hour.

Automatic distiller system

In this system, a water pipe is connected to produce pure water continuously. The systems can be controlled by electronics or float valves to cease production during the holding tanks reach a specific level. It can be possible to store 3 to 25 liters of water in this distiller system.

Water Distiller Operating Procedure

Firstly, this machine is plugged into a power source and turned on after adding water to the boiling chamber. It boils off the solution when the water reaches the boiling point in the boiling chamber. Then the steam is produced that rises into the cooling system leaving behind bacteria, fluorides, and other harmful substances. The condenser helps to condensate the vapor into liquid. The activated carbon filter removes the pollutants from the liquid. Finally, water droplets can be collected into a container for further use.

Applications of Water Distiller

Distilled water helps to increase the flow of electricity in lead-acid batteries. It is very suitable for dilution of the coolant for the car’s radiator. It helps to prevent any mineral build-up or settling of bacterial growth. This water is used for various household purposes and cleaning tasks, such as ironing, preventing a scale build-up from minerals, car washing, aquariums, etc. Distilled water can be used in the medical and scientific industries for experiments and cleanliness purposes.

Maintenance of Water Distiller

The water distiller should be designed for easy cleaning. It should have an automatic flush system. The scale should be removed to get proper boiling facilities. A vinegar solution can be used for proper cleaning of its internal surface.

Important to read