A compressor is a mechanical piece of equipment used to raise pressure in various types of compressible fluids, or gases by mechanically decreasing its volume. Natural gas, oxygen, nitrogen, carbon dioxide, ammonia, and other industrially important gases are also compressed. This equipment is widely used in different fields to power air tools, paint sprayers, abrasive blast equipment; phase shift refrigerants, etc.

It is also used for air conditioning, refrigerators; and to propel gas through pipelines; etc. Compressors are mainly divided into two categories namely centrifugal (or dynamic or kinetic) and positive-displacement types.

Compressor Definition

It is mechanical equipment that is designed to raise the pressure of a gaseous material by decreasing its volume. It is considered an important component of refrigeration systems and the “heart of the cooling system”. The working activities of this tool are about the same to the pump. A lot of compressible fluids, or gases, the most common of these being air can be compressed easily by using this equipment. It is widely used in the chemical processing industries, pharmaceutical industries, food industries, paint industries, refrigerator industries, air conditioning industries, and various industries.

Compressor Working Principle

The working principle of this device is about the same as pumps because both of the tools have the ability to increase the pressure on a fluid and both can transport the fluid through a pipe. However, the focus of this device is to change the density or volume of the taken fluid, which is mostly only achievable on gases. We know that gas molecules can be compressed, whereas liquids are relatively incompressible. So this equipment is very suitable for liquids to pressurize and transportation purposes.

It works with compressible fluids like gas or air by following a compression process. The compressible fluids are pumped from a small chamber to a larger chamber and increase the pressure. The pressure regulators and safety valves in this device help to ensure the pressure remains stable at the time of the compression process. It is also equipped with a controller and monitoring system to help the operator control and monitor the compression. The monitoring system of this device helps to properly monitor the air pressure, temperature, and flow to confirm the compressor works efficiently and safely.

Compressor Functions

There are many functions of this equipment ranging from household to agriculture. The most important functions of the compressor are discussed below:

It helps to increase the gas or air pressure from a smaller chamber to a larger chamber which is very essential function in petrochemical and oil industries, where gas and air play an important role in production.

It supplies air or gas for high-pressure applications when required essentially like pumping water, cooling systems, and charging batteries in electronic equipment. The air or gas pressure can be raised by this equipment to ensure optimal performance in the application.

This device works efficiently as the driving medium to ensure that the air entering the system is clean and free from any type of contaminants in a building control system.

It can compress air or other gases into a smaller volume in a short period of time and is used in a variety of tools efficiently and effectively.

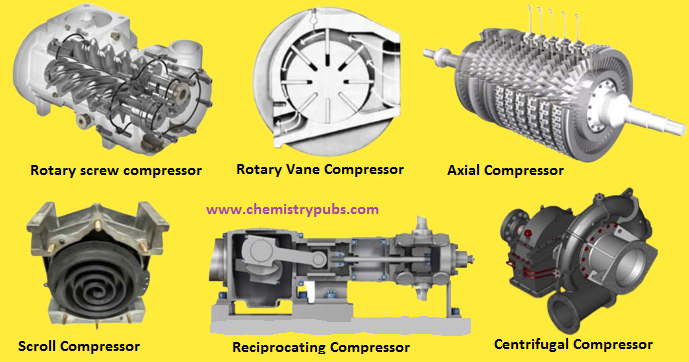

Compressor Types

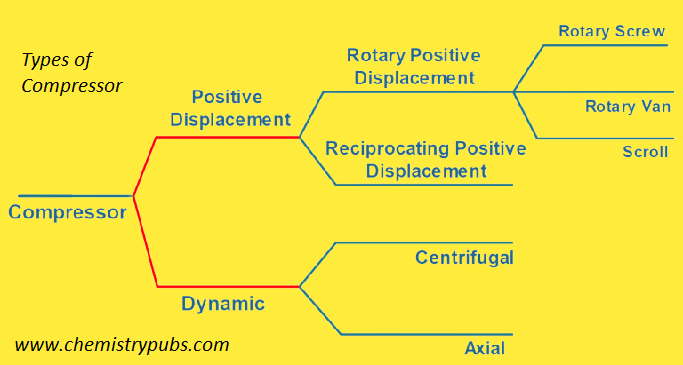

This mechanical piece of equipment is used to pressurize air or gases just as Pumps are used to pressurize liquids and transport them through pipes. There are mainly two types of compressors namely positive displacement type and dynamic type.

1. Positive Displacement Compressor

This device consists of various mechanical parts that draw in gas in steps of discrete volume from the inlet of the compressor. It helps to reduce the volume of the air or gas raises the pressure of the gas and discharges the gas from the outlet of this device.

This equipment can be divided into two types namely Rotary type and Reciprocating type.

Rotary Positive Displacement Compressor

This device has the rotating principle to draw in the gas and also to discharge it. There are four types of this device which discussions are given below:

Rotary Screw Compressor

It contains a pair of helical screws namely a male screw and a female screw. The rotating properties of this equipment help to draw the gases from the input of the compressor in a continuous sweeping motion.

Rotary Vane Compressor

It consists of a rotor mounted with vanes. The gas or air molecule will not be able to leak through the clearance between the wall and the edges of the vanes due to the touch of the walls of the housing. The rotating movement of this device helps to increase and decrease the volume of the gas.

Scroll Compressor

The rotating principle of this equipment is the pair of interleaved spiral-like vanes. Among the scrolls, one of the scrolls is fixed, whereas the other scroll operates eccentrically to compress gases efficiently.

Reciprocating Positive Displacement Compressor

It consists of a piston and crankshaft. The air or gaseous molecules are sucked inside this device and the crankshaft principle helps to produce a reciprocating motion to move the piston in order to compress the gas. This device performs the single-acting or double-acting. The air or gaseous molecules interact with the cylinder only once during the single-acting mechanism, whereas the gas interacts with the cylinder twice during the double-acting mechanism.

2. Dynamic Compressor

It consists of rotating blades to run the movement of gases and compresses them inside. It is widely used for large-scale operations. There are two types of this device which discussions are given below:

A. Centrifugal Compressor

It consists of an impeller that rotates at high speed sucks in gas and accelerates it to high velocities. The kinetic energy of moving gaseous molecules can be converted into static energy at the time of discharging high-velocity gas through a section of increased area.

B. Axial Compressor

It contains a set of airfoils which are stacked in a row. One of the airfoils rotates but the others remain stationary. The rotating characteristics of an airfoil compress the air or gaseous molecules. The high flow rate of this device can be achieved by changing the design based on the requirements.

Applications of compressor

It is an essential tool for the manufacture and blow molding of PET plastic bottles and various types of containers.

It is used in turbojets and turbofans to compress the air required for fuel combustion.

It is used to transport purified natural gas from the production site to the consumer without an external power source because it is driven by a motor fueled by gas bled from the pipeline.

It is used in petrochemical plants, chemical plants, and natural gas processing plants to compress the fluids.

It is used to supply low-pressure air (10 to 20 bar) for breathing purposes in hospitals.

It is used in submarines to store air for further use in displacing water from buoyancy chambers to adjust buoyancy.

It is very much used in refrigeration and air conditioner equipment to move heat in refrigerant cycles.

It is used in various industrial and manufacturing sites that require compressed air to power pneumatic tools.

Frequently Asked Questions (FAQs)

What is a compressor?

It is an essential mechanical device that is designed to increase the pressure of air or various gaseous materials by decreasing its volume.

What are the types of compressors?

It is generally two types namely positive displacement type and dynamic type. Positive displacement type is divided into categories namely rotary positive displacement type and reciprocating positive displacement type. The dynamic compressor is divided into two categories namely centrifugal and axial types.

What are the industrial applications of compressors?

It is used in the chemical processing industries, pharmaceutical industries, food industries, paint industries, refrigerator industries, air conditioning industries, and various industries to compress air or gaseous materials by decreasing the volume.

What is an air compressor?

It is a mechanical device that is used to receive the ambient air from the surroundings and discharge it at a higher pressure region. It has the ability to convert mechanical power into potential energy stored in compressed air.

What is the function of an air compressor?

It is used to pump air and increase its pressure which can be used in various applications, such as inflating car tires, charging electronic equipment batteries, and supplying air for pneumatic tools.